Metal tube fabrication involves the process of cutting, bending, and shaping metal tubes to different shapes and sizes. It is commonly used in the production of products like furniture, automotive parts, and machine parts. The process of metal tube fabrication has revolutionized the manufacturing industry, making it possible to produce complex and intricate parts and structures.

One of the significant advantages of metal tube fabrication is its versatility. It is suitable for a wide range of materials, including stainless steel, aluminum, copper, and brass. This process allows for the creation of custom parts, which is essential for unique and specialized products.

Furniture manufacturers, for example, can use metal tube fabrication to create custom pieces that fit specific designs and customer preferences. Additionally, automotive parts manufacturers can use it to produce customized parts, which are essential in ensuring the safety and functionality of their products.

Another benefit of metal tube fabrication is its cost-effectiveness. The process requires minimal labor, and the components can be produced in large quantities, reducing the cost per item. Manufacturers with specialized machines and skilled technicians can create complex parts at a minimal cost and with exceptional quality.

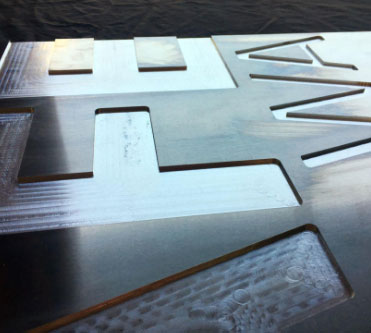

Quality is a significant concern in the manufacturing industry, and metal tube fabrication has not disappointed in this regard. Unlike traditional metal fabrication methods, this process produces components with incredible accuracy and precision. The use of specialized machines and software ensures that the parts produced meet precise tolerances and specifications.

In conclusion, metal tube fabrication is a game-changer in the manufacturing industry. Its versatility, cost-effectiveness, and precision make it an ideal option for creating complex and customized parts. With the help of skilled technicians and specialized equipment, manufacturers can produce parts to meet the ever-increasing demands of the market. Metal tube fabrication is not just a process, but an art that brings out the beauty and functionality of metal structures, machines, and tools.