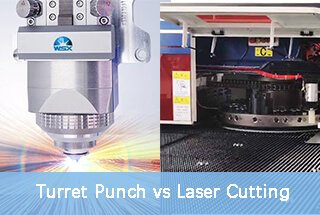

Laser cutting has revolutionized the manufacturing industry. It offers a precise, fast, and cost-effective way to cut various materials, including metal, plastic, and wood. Laser plate cutting, in particular, has become increasingly popular, and for good reason. In this article, we will explore the benefits and advantages of laser plate cutting and why it is a preferred choice for many businesses.

What is Laser Plate Cutting?

As the name implies, laser plate cutting is a process that uses a laser beam to cut a flat piece of material, typically metal. The laser beam is highly concentrated and directed through a series of mirrors to the material, creating a clean and precise cut. The process is computer-controlled, which means the design is first programmed into the software, and the laser then cuts the material according to the design specifications.

Benefits and Advantages of Laser Plate Cutting

1. Precision and Accuracy

One of the primary benefits of laser plate cutting is its ability to achieve high levels of precision and accuracy. The laser beam is incredibly precise, allowing for intricate cuts in complex shapes and sizes. This level of accuracy is difficult to achieve with traditional cutting methods, making laser plate cutting a preferred choice for many businesses, especially those in the aerospace, automotive, and medical industries.

2. Faster Processing Times

The laser beam is incredibly fast, allowing for high processing speeds compared to traditional cutting methods. This means that laser plate cutting can produce large quantities of precisely cut parts in a short amount of time, which translates to cost savings for businesses.

3. Greater Material Efficiency

Laser plate cutting is a non-contact cutting method, which means that there is no physical contact between the material and the cutting tool. This results in less material waste, which is a significant advantage for businesses that are looking to minimize material costs.

4. Versatility

Laser plate cutting can cut a wide range of materials, including metals, plastics, and wood. This versatility makes it an excellent choice for businesses that work with multiple materials and need to switch between them frequently.

5. Reduced Maintenance Costs

Another advantage of laser plate cutting is that it requires minimal maintenance. Since there are no physical cutting tools involved, there is no need for reshaping or sharpening the tool, which is a cost-saving advantage for businesses.

Conclusion

Laser plate cutting is a precision cutting process that offers numerous benefits and advantages over traditional cutting methods. It provides businesses with greater accuracy, faster processing times, material efficiency, and versatility. Additionally, it requires minimal maintenance, which translates to cost savings. If you are looking for a high-quality cutting method for your business, laser plate cutting is definitely worth considering.