If you work in the manufacturing industry, you've probably heard of butt welding. Simply put, it's a welding technique that involves joining two pieces of steel together to create a strong, permanent bond.

But what makes butt welding stand out from other types of welding? Well, for starters, it's one of the most efficient and cost-effective ways of joining steel. This is because it eliminates the need for additional materials like bolts or screws, which can be pricey.

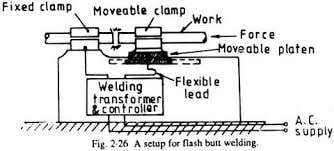

Now, let's dive a little deeper into how butt welding works. There are two main methods used in butt welding: heating up two pieces of steel or applying pressure. Often, both methods are used in combination to create the strongest weld possible.

One of the most important things to keep in mind when butt welding is penetration. This means ensuring that the weld goes all the way through both pieces of steel, creating a complete bond. This is especially important when working with thicker pieces of steel. In order to achieve this penetration, the edges of the steel may need to be prepared ahead of time.

But what about imperfections? Well, a strong butt weld will have as few imperfections as possible. This is achieved by controlling the heat input and reducing the size of the weld. However, to maintain the strength of the weld, double butt welds may be used.

In conclusion, butt welding is an efficient, cost-effective method for joining steel. By using a combination of heat and pressure, a strong bond can be achieved without the need for additional materials. With proper preparation and attention to detail, imperfections can be minimized, resulting in a high-quality finished product.